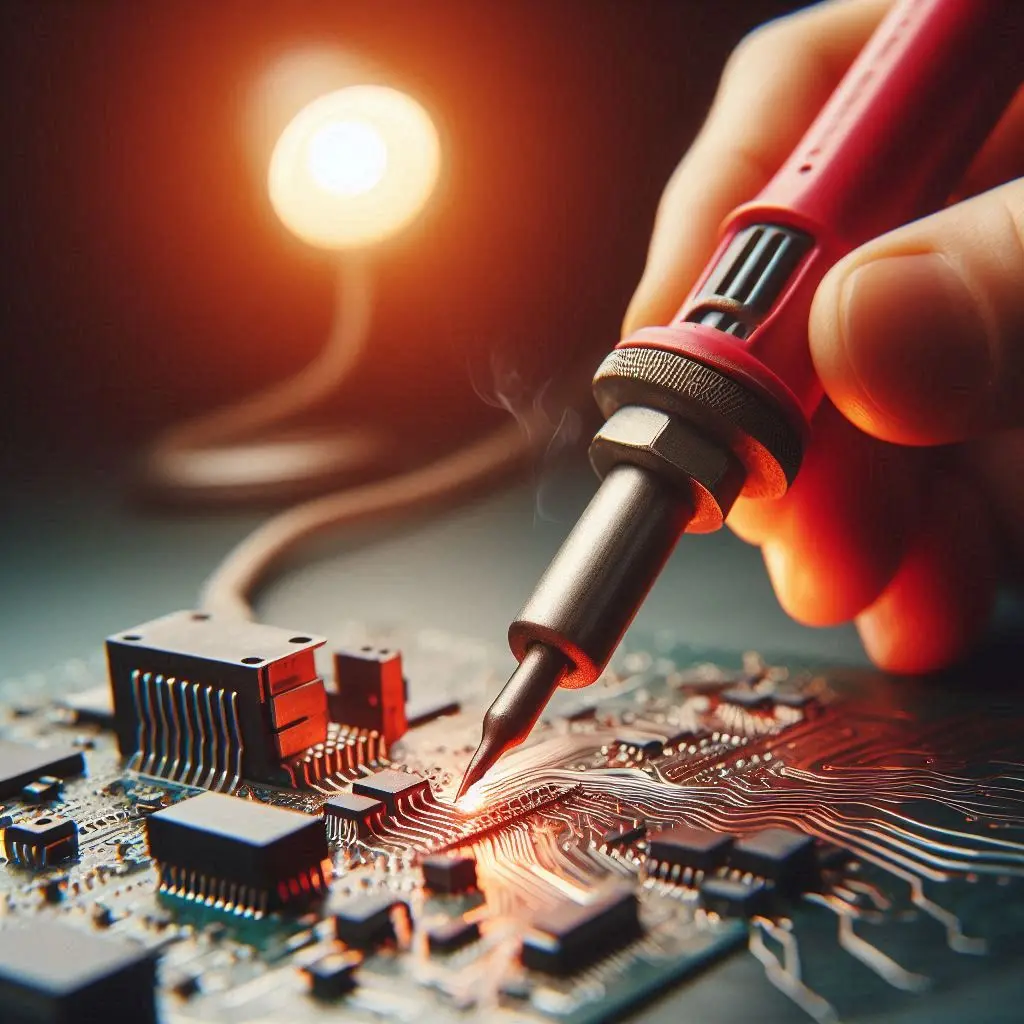

Whatever electronic device we have, it gets damaged at some point, so we used to take the damaged electronic device to a repair shop. You must have seen a technician joining two wires or metals with the help of a tool. That tool is called a soldering iron. So in this blog, we will learn about what a soldering iron is, how it works and how many types there are.

Table of Contents

What is Shouldering Iron?

It is a tool which we can use with one hand and we use this tool to join two metals easily and in less time. the process by which all this happens is called soldering and in this soldering process, we melt a soft metal called solder to join two different metals.

Different types of Soldering Iron

There are 3 types

- Pencil Soldering Irons

- Soldering Stations

- Cordless Soldering Irons

- Soldering Guns

- Pencil Soldering Irons

It is a portable, pen-shaped tool. It heats up quickly and is best for small, detailed work.

- Soldering Station

Soldering stations are important tools for electronics and DIY applications, used to join electronic components together. It contains a soldering iron and a temperature control device. Advanced models may include additional features such as digital displays, and adjustable temperature settings.

- Cordless Soldering Iron

Cordless soldering irons are portable tools that can be soldered without being connected to a power supply. Rechargeable batteries power them. These soldering irons offer convenience and flexibility, enabling users to work on various projects such as electronics repair or jewellery making.

- Soldering Gun

It consists of a handle, a trigger, and a metal tip that heats up when activated. They heat up quickly, making them suitable for tasks that require precision and speed. They are commonly used in electronics repair, hobbyist projects, and manufacturing.

Choose the Best Soldering Iron for You

Before making any decision, you must first know what your requirements are. So, read the points below to know which is better for you.

- Consider the nature of work:

If you do some work related to electronics or electrical equipment then a pencil soldering iron would be better for you, but if you want to work on a large scale then you can consider a soldering station or a soldering iron with special features.

- Temperature control

Not all soldering irons give the same amount of heat, so if you want to buy one that gives the temperature according to your needs then you need a soldering iron with a temperature control feature.

- considering power

You can consider the power of a soldering iron according to the speed of your work. Generally, a good one ranges from 20 to 60 watts.

- Price and budget

Although many types of soldering irons are available in the market, you can choose one according to your budget and price. But try, if you have a good budget then you can consider a good one for better performance.

Safety during soldering

- Work in the right place

Select a clean and safe place for soldering. After the work is done, make sure to cool down the tip of the iron aby place it at a safe distance.

- wear safety PPE

Before working, wear safety equipment so that heat and smoke do not harm your skin, such as safety glasses, and safety gloves.

- Electric connection

Before soldering, check the electric connection. Remember that you have to be careful during soldering work and be cautious to prevent the electric connection from getting damaged. Also, before you plug the soldering iron in any socket, make sure that the socket is in good condition and not broken.

- Keep in close position

After the work is done, make sure to turn it off put it back in its place, and leave it to cool down

You can learn more about what safety precautions should we take during soldering.

Maintenance and Care for Your Soldering Iron

Clean the soldering tip as needed. After work is done, wipe off any dirt or toxins deposited on the tip with a sponge or cleaning item and keep the tip clean.

Tip tinning

It is necessary to tie the iron’s tip before using it. This protects the tip from rusting and helps to transfer heat properly.

How to Use?

- Set up Security:

First, wear your safety equipment so that nothing gonna happen wrong with you

- Prepare the soldering iron:

As soldering takes time to heat up, you need to leave it for some time so that it can properly heat.

- Prepare the soldering area:

Properly clean the area you want to solder.

- Include solder

Hold the iron over the solder wire for some time so that the shoulder can melt and after the solder melts, place the melting solder where you want to make the joint.

- Proper Soldering:

After placing the shoulder on the joint, let it cool down so that it solidifies properly where you want to make the joint. After that, check whether the joint is done properly or not by pulling it a little.

- Finish Soldering:

After the soldering is over, keep it in its place where it can cool down.

By following this simple step, you can complete a complete soldering work and you will not have any problem in soldering.

Conclusion

Using a soldering iron is also a skill which we can gradually improve. In the beginning, we will have some difficulty in soldering, our soldering will not be perfect, but with time all this will be fine and we will also be able to do soldering properly, while doing soldering we have to follow some safety precautions so that nothing wrong happens to us while doing soldering, after following the right advice we can get our work both successfully and safely, I hope this blog will be helpful to you in doing soldering work and will boost your confidence so that you can do soldering properly, thank you for reading this blog, have a nice day

Learn more about Understanding PCB (Printed Circuit Board): A Simple Guide Students